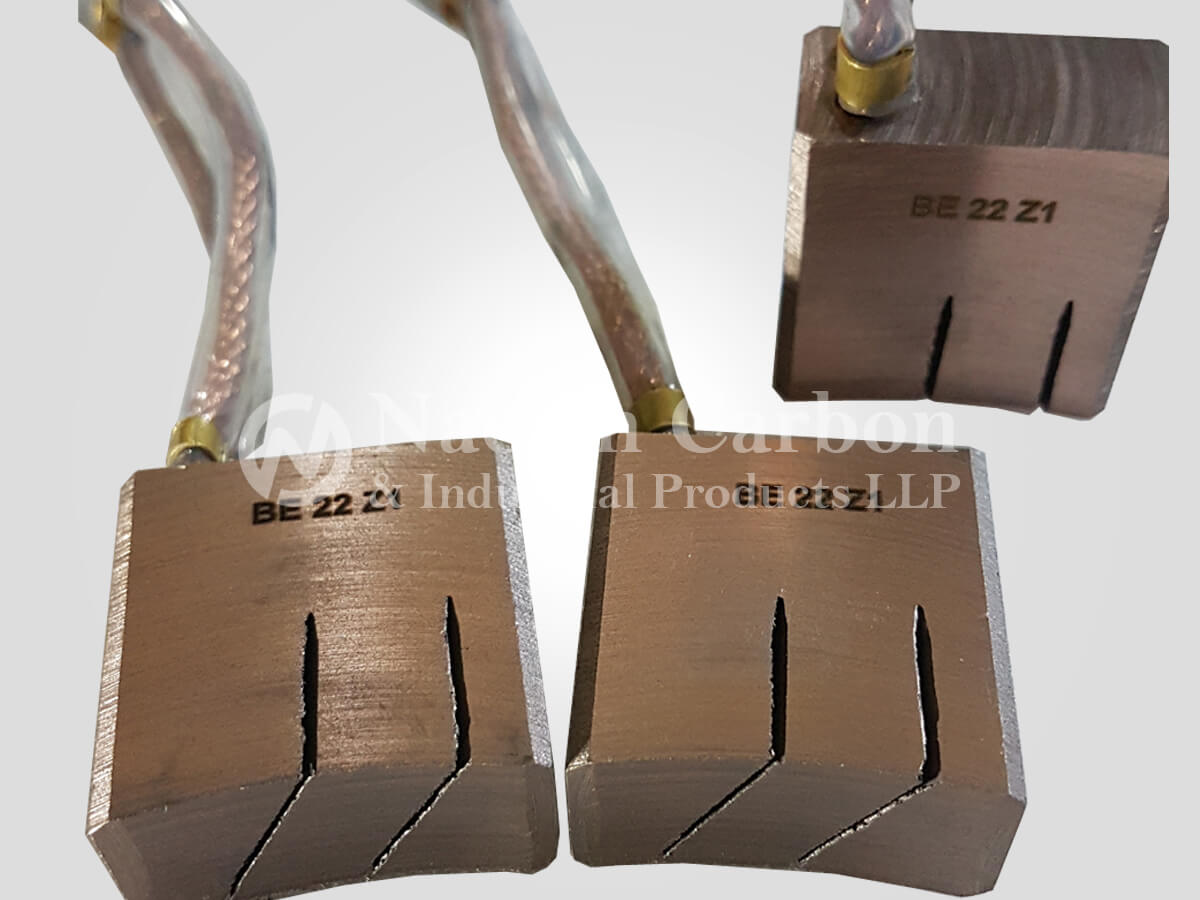

Range of Carbon Brush

Carbon Brush

Our objective is to develop the best designs to maximize Brush life and performance for a given application. The possible permutations of Brush configurations are enormous.

Basic Carbon materials range from Copper or Electro-Graphite, to Resin Bonded and Silver Graphite's or a special blend of these materials.

We work with more than 100 different Carbon Grades of high quality material. Carbon Brushes are manufactured in all shapes and sizes, tolerance to suit the customer's needs.

The main categories of Brushes are:

Natural Graphite Brushes

The natural graphite is main raw material of this class of brushes. Here pitch and resin are used as binders. They are baked at about1000℃.

These classes of brushes are provided with better lubricating and current collecting performance. The natural graphite brushes are respectively used with the slip

rings of small and medium size DC motor and high speed turbo-generators.

Electro Graphite Brushes

These classes of brushes consist of various kinds of carbon powders such as carbon black, coke, graphite and so on. They must undergo high

temperature treatment at about 2500℃to make all kinds of carbonic material convert to a micro-crystalline form of artificial graphite.

These classes of brushes have excellent characteristic of commutating and self- lubricating, widely applied to all kinds of AC and DC

motors with the advantage of long service life and less wear ability of the commutators. Electro graphite's are generally porous, but

may be treated with substances to increase Brush strength and overall operating ability.

Metal/Copper Graphite Carbon Brushes

Metal Graphite carbon brush consist of a metal powder composition ranging from 4% to 98% metal ( Copper, plus metal alloys plus graphite ).

These classes of brushes are applicable to low voltage electrical machines with heavy load and ordinary requirements of commutation.

They are used on a variety of applications because of their low resistivity.

Silver Graphite Carbon Brushes

Silver graphite materials are mainly used on Tachogenerators, or for measuring purposes, or on ships earthing applications.

Resin Bonded Carbon Brushes

These classes of material are identified with letters such as IM, RX & BG. The grades are based on Natural and/or Electro-Graphite material,

mixed with artificial resin. This type of bond produces a high electrical resistance which endures the grades with extremely good commutating

abilities combined with high contact drop & low friction. These materials are suited to small DC machines and Three Phase AC commutator motors.

We manufacture carbon brushes for major applications such as Wide range of Slip ring & Commutator Motors, Steel Industries, Mining Industries,

Cement Mills, Crane Applications, Fork Lifts, Steam / Hydro Exciters, Generators & Motors for Paper Mills, Shipping, Wind Generation,

Power Generators, Plastic Industries and all types of A.C and D.C Motors.

Carbon Grades of Morgan AM&T, Schunk, Mersen-Carbon Lorrane

MORGAN AM&T

405; 402; 457; 441; 442; 048; 5; 543; 546K; 559; 634; 676N; 840; 840K; 850; 888; 9101; 9234R; 9613; A; A0; A29; AX5; AY; AYK; AZY;

B3; C15; C151; C157; C39; C4; C6; CJA5H; CM; CM0; CM122; CM140; CM1S; CM2; CM21; CM28; CM3H; CM4; CM41; CM4684; CM4943; CM5; CM5B; CM5H;

CM6; CM61; CM8; CM8100; CM8121; CM817; CM835; CM845; CM861; CM880; CM9; CM9133; COPHITE1; COPHITE2; COHITE3; COPHITE4; CY280; CY3; CY3TA;

DE2; DE21; DE3; DE4; DE46; DE7; DE700; DE8; DE9000; DM100; DM20; DM3632A; DM4A; DM4D; DM5A; DM5D; DM2001; DWK; E; EG10; EG101; EG105; EG105S;

EG109; EG11; EG111; EG112; EG114; EG116; EG116S; EG119; EG11S; EG12; EG121; EG123; EG124; EG128; EG12K; EG131; EG132; EG133; EG14; EG14D; EG16;

EG16S; EG16T; EG17; EG18; EG2; EG224; EG225; EG236; EG236S; EG238; EG251; EG251R; EG259; EG260; EG260Z; EG263; EG267; EG268; EG269; EG275; EG277;

EG283; EG284; EG295AC; EG3; EG4; EG451; EG501; EG571; EG5763; EG5937; EG6345; EG6434; EG6632; EG6749; EG6749N; EG801; EG809; EG810; EG8101; EG835;

EG845; EG855; EG8565; EG8866S; EG898; EG9610; EG95; EGOR; F83; DE7; DE7000; EG0/EG0R; EG116; EG116S; EG12; EG14D; EG18; EG224; EG236; EG236S; EG251;

EG259; EG260; EG275 / ME778; EG283; EG295AC; EG6749N; EG8101; H803; HAMEG18; HM2; HM477; HM5; HM6; HM6R; HRG; IM100; IM102; IM103; IM19; IM2; IM23;

IM26; IM3; IM31; IM6; IM62; IM7; IM812; IM8876; IM9101; IM9115; IM9117; M3; M300; MD14; MD4; ME377; ME398; ME770; ME778; MY258; MY258A2; MY258S; MY3D;

MY7A; MY7B; MY7D; MYX259; N1; N18; N19; N19X; N2; N20; N2000; N315; N4; N43; N44; N48; N6; ME353; ME373; ME377; ME393; N19; N19X; N48; N6000; PH; PM11;

PM423; PM50; PM50P; PM60; PM70; PM805; PM85; PM9; R15; R64; SA25; SA2522; SA35; SA3513; SA3532; SA3538; SA40; SA45; SA4513; SA4542; SA4548; SA4588;

SA50; SM; SM2; SM3; TA35; TA35R; TA45; TA45A2; TA45R; C12; H100; PM50P; 634; HM24; CM1S; CM3H; CM5H; CM9; GM61; SM3; SM9173; DM4D; IM26/IM9101;

IM31/IMX31; IM6; IM8876.

SCHUNK

S11; S15; S30; S13/F19; C40Z3; U1736; F19/S13; E104; HG; E49; E46F3; E468; HG5634; HG2634; A12S; K14Z3; C80X; A24; E101; E46X; C40Z3; FL16;

FF10; E108(M); F61; F63; F49; E191M; E46X(M); E79X; E55; E49X; F51; C72; A41X; A24X; C80; C80X; S13; K14Z3; E43; S13/F19; B24; C40Z3; A20; E46X;

E105; C40Z3; B20; E43Z3; U7044; U1762; F51R72; E43Y3; A30; E108; F61; F63; A24; B14Z1; B24; S137; L41F7; L82F7; E55; E101M; E108; E46; E46F3; E46X;

E468; E55; E220; F51; F49; B14Z1; B25; C40Z3; BH25; BH25C.

MERSEN - CARBON LORRANE

A121; A122; A176; A210; A252; LFC501; LFC554; EG34D; EG398P; EG396; EG362; EG40P; EG313; EG367; EG332; EG387; EG300; EG98; EG 369; EG319P; EG321;

EG365; EG7099; EG 9599; EG9117; EG8019; EG8067; EG8220; EG7079; EG341; EG6489; EG8285; EG7655; BG412; BG469; BG400; C6958; CG33; C8386; CG651; CG626;

CG665; CG75; OMC; MC79P; MC12; MC689; M609(4); M673(4); M9426; M621; M9020; M8295.